EBARA submersible pumps are engineered to handle a wide variety of materials and applications. Our line of submersible pumps is suitable for a range of markets including municipal water, municipal wastewater/sewage, residential, industrial, and commercial.

Sturdy design,

corrosion resistant

Practical and easy

to use

Possibility to use

in fixed

Corrosion

resistant

Mobile

installations

AISI 304 stainless steel submersible pump with the mechanical seal in oil bath and oversized oil chamber. These features make the pump reliable, durable and corrosion-resistant.

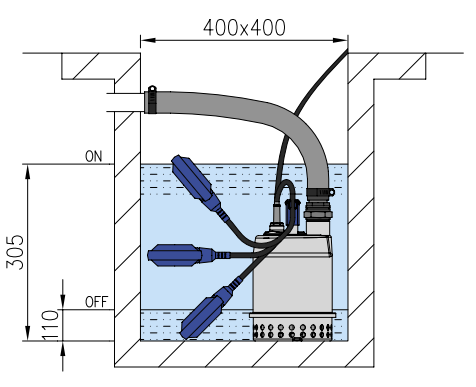

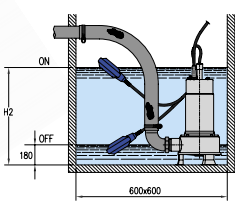

The EBARA OPTIMA electric pump has great versatility of installation (fixed or mobile) due to the possibility of choosing between the vertical magnetic float switch (of reduced size) or the cable float switch (MA).

These solutions also allow you to choose the best pump insertion option according to the space available.

OPTIMA

Submersible pumps in AISI 304

| Power KW / HP |

Voltage V |

Discharge in. |

Flow Rate L/min |

Head M |

Cable M |

|---|---|---|---|---|---|

| 0.25/0.33 | 230 | 1 1.4" | 75 | 7.5 | 10 |

B

A

| Cycle (Hz) | A | B | N.W. (kg) |

| 50/60 | 273 | 167 | 4.4 |

Technical data

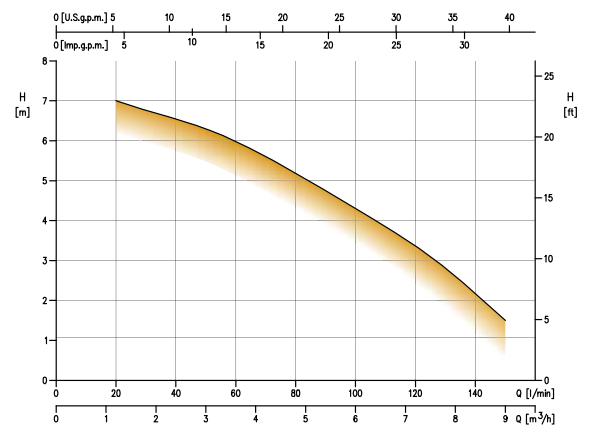

Flow rate: from 1.2 to 9 m³/h.

Total head: From 1.5 to 7.6 m.

Max. temperature of the liquid: +50°C

Poles: 2

Max. solids passage: 10 mm

Insulation class: F

Protection degree: IP68

Voltage: Single-phase 1~230V ±10%.

Max. immersion: 5 m with 10 m cable / 2 m with 5 m cable.

Materials

Pump body: Stainless steel AISI 304 (EN 1.4301).

Impeller: PPE + PS reinforced with glass fibres.

Shaft: Stainless steel AISI 303 (EN 1.4305) (part in contact with liquid.

Mechanical seals: Ceramic/Carbon/NBR (mechanical seal) / QQV Silicon Carbide/FPM (special mechanical seal) / NBR (lip seal).

BEST ONE

Fully submersed electric pumps in AISI 304

AISI 304 stainless steel submersible pump with mechanical seal in Ceramic/Carbon/NBR and oversized oil chamber that increase the life and reliability.

BEST ONE has a semi-open impeller, while BEST ONE VOX is equipped with vortex type impeller, to ensure a greater free passage and reduce the possibility of clogging.

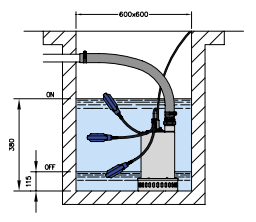

The electric pumps offer great versatility of installation (fixed or mobile) due to the possibility of choosing between the vertical magnetic float switch (of reduced size) or the float switch.

| Power KW / HP |

Voltage V |

Discharge in. |

Flow Rate L/min |

Head M |

Cable M |

|---|---|---|---|---|---|

| 0.25/0.33 | 230 | 1 1.4" | 150 | 9 | 10 |

B

A

| Cycle (Hz) | A | B | N.W. (kg) |

| 50/60 | 273 | 167 | 4.6 |

Technical data

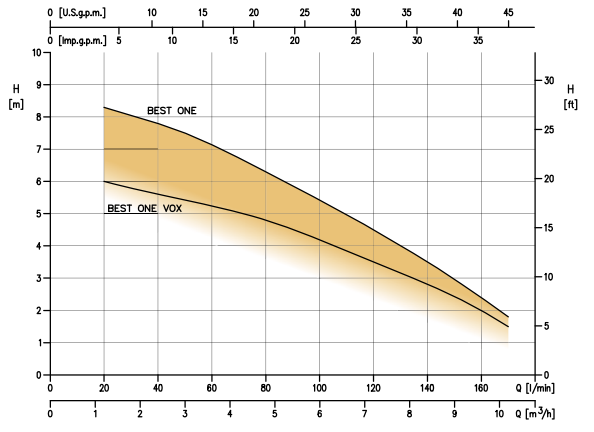

Flow rate: from 1.2 to 10.2 m³/h

Total head:

From 1.8 to 8.3 m for BEST ONE and From 1.5 to 6 m for BEST ONE VOX

Max. temperature of the liquid: +50°C

Poles: 2

Max. solids passage: 10 mm / 20 mm for VOX version (Vortex)

Insulation class: F

Protection degree: IP68

Voltage: Single-phase 1~230V ±10% / Three-phase 3~400 ±10%

Max. immersion: 5 m with 10 m cable / 2 m with 5 m cable

Materials

Pump body: Stainless steel AISI 304 (EN 1.4301)

Impeller: Stainless steel AISI 304 (EN 1.4301)

Shaft: Stainless steel AISI 303 (EN 1.4305) (part in contact with liquid

Mechanical seals:

Ceramic/Carbon/NBR (mechanical seal) / NBR (lip seal)

BEST 2-5

Submersible pumps in AISI 304

Submersible pump entirely in AISI 304 stainless steel, with double mechanical seal in oil chamber.

Practical and easy to use, BEST 2-5 electric pumps are also available with float, thus increasing their versatility of use

| Model | Power KW / HP |

Voltage V |

Discharge in. |

Flow Rate L/min |

Head M |

Cable M |

|---|---|---|---|---|---|---|

| Best 2 | 0.55/0.75 | 230 | 1 1/4" | 250 | 13 | 10 |

| Best 3 | 0.75/1 | 230 | 1 1/2" | 275 | 13 | 10 |

| Best 4 | 1.1/1.5 | 230 | 1 1/2" | 325 | 13 | 10 |

| Best 5 | 1.5/2 | 400 | 1 1/2" | 350 | 13 | - |

B

A

| Model | Cycle (Hz) | A | B | N.W. (kg) |

| Best 2 | 50/60 | 352 | 210 | 12 |

| Best 3 | 50/60 | 352 | 210 | 12.7 |

| Best 4 | 50/60 | 377 | 210 | 13.8 |

| Best 5 | 50/60 | 377 | 210 | 13.5 |

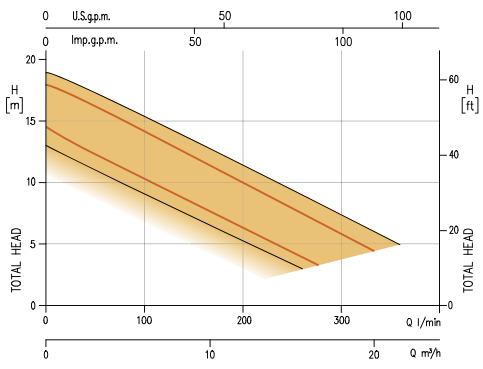

Technical data

Flow rate: from 1.2 to 21.6 m³/h

Total head:

From

2.9 to 18.4 m

Max. temperature of the liquid: +50°C

Poles: 2

Max. solids passage: 10 mm

Insulation class: F

Protection degree: IP68

Voltage: Single-phase 1~230V ±10% / Three-phase 3~400 ±10%

Max. immersion: 7

m with 10 m cable

Materials

Pump body: Stainless steel AISI 304 (EN 1.4301)

Impeller: Stainless steel AISI 304 (EN 1.4301)

Shaft: Stainless steel AISI 303 (EN 1.4305) (part in contact with liquid)

Mechanical seals:

Upper part in Carbon/Ceramic/NBR (motor side) / lower part in Silicon Carbide/NBR (pump side)

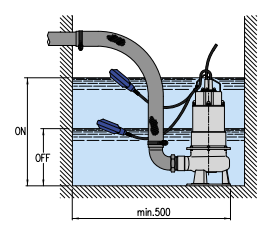

Submersible pump entirely in AISI 304 stainless steel and open vortex impeller, which can be used in fixed and mobile installations.

The RIGHT electric pump is also available with a float switch that allows for wide use.

RIGHT 75/100

Submersible pumps in AISI 304

| Model | Power KW / HP |

Voltage V |

Discharge in. |

Flow Rate L/min |

Head M |

Cable M |

|---|---|---|---|---|---|---|

| Right 75 | 0.55/0.75 | 230 | 1 1/2" | 240 | 2 | 10 |

| Right 100 | 0.75/1 | 230 | 1 1/2" | 240 | 10.5 | 10 |

B

A

| Model | Cycle (Hz) | A | B | N.W. (kg) |

| Right 75 | 50/60 | 405 | 186 | 10.5 |

| Right 100 | 50/60 | 430 | 186 | 12 |

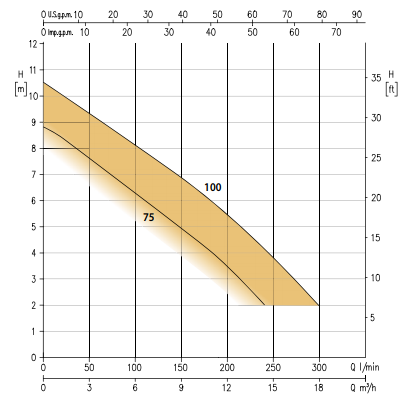

Technical data

Flow rate: Up to 18m³/h

Total head:

Up to 9.5m

Max. temperature of the liquid: +50°C

Poles: 2

Max. solids passage: 35 mm

Insulation class: F

Protection degree: IPX8

Voltage: Single-phase 1~230V ±10% / Three-phase 3~400 ±10%

Max. immersion: 7

m with 10 m cable / 2 m with 5 m cable

Materials

Pump body: Stainless steel AISI 304 (EN 1.4301)

Impeller: Stainless steel AISI 304 (EN 1.4301)

Shaft: Stainless steel AISI 303 (EN 1.4305) (part in contact with liquid

Mechanical seals:

upper part in Carbon/Ceramic/NBR (motor side) / lower part in Silicon Carbide/NBR (pump side)

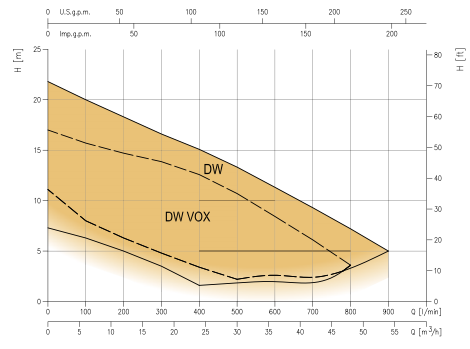

AISI 304 stainless steel submersible pump and single-channel impeller (DW) or vortex impeller (DW VOX) for fixed and mobile installations. The DW - DW VOX electric pump has two versions for connection to pipes:

• Threaded for DW - DW VOX

• Flanged for DWF - DW VOXF

DW SERIES

Submersible pumps in AISI 304

| Model | Power KW / HP |

Voltage V |

Discharge in. |

Flow Rate L/min |

Head M |

Cable M |

|---|---|---|---|---|---|---|

| DW/A 75 | 0.55/0.75 | 230 | 2" | 450 | 11 | 10 |

| DW/A 100 | 0.75/1 | 230 | 2" | 550 | 13 | 10 |

| DW/A 150 | 1.1/1.5 | 230 | 2" | 650 | 15 | 10 |

| DW/A 200 | 1.5/2 | 230 | 2" | 750 | 18 | 10 |

| DW/A 300 | 2.2/3 | 230 | 2" | 900 | 22 | 10 |

B

A

| Model | Cycle (Hz) | A | B | N.W. (kg) |

| DW/A 75 | 50/60 | 486 | 228 | 16 |

| DW/A 100 | 50/60 | 516 | 228 | 18 |

| DW/A 150 | 50/60 | 516 | 228 | 19.4 |

| DW/A 200 | 50/60 | 516 | 228 | 20 |

| DW/A 300 | 50/60 | 546 | 228 | 25.8 |

Technical data

Flow rate: Up to 54 m³/h for DW / Up to 48 m³/h for DW VOX

Total head:

Up to 20 m for DW / Up to 15.7 m for DW VOX

Max. temperature of the liquid: +40°C

Poles: 2

Max. solids passage: 50 mm

Insulation class: F

Protection degree: IPX8

Voltage: Single-phase 1~230V ±10% / Three-phase 3~400 ±10%

Max. immersion: 7

m with 10 m cable

Materials

Pump body: Stainless steel AISI 304 (EN 1.4301)

Impeller: Stainless steel AISI 304 (EN 1.4301)

Shaft: Stainless steel AISI 303 (EN 1.4305) (part in contact with liquid

Mechanical seals:

upper part in Carbon/Ceramic/NBR (motor side) / lower part in Silicon Carbide/NBR (pump side)

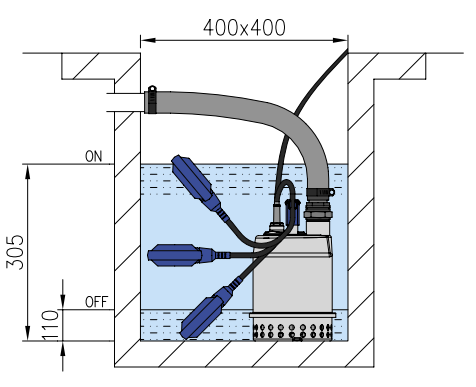

If the pump is fitted with a float switch, the latter must have enough room to move freely, so that it can switch and ensure a proper pump operation.

Please follow the directions provided in the instruction manual when the installation requires float switches that are fixed to the tank and are driven by a distribution board.

Strictly follow the directions provided in the instruction manual.

Yes, anyhow this operation has to be carried out by a specialised technician or at an authorised EBARA Service Centre. This avoids improper connections that can adversely affect the pump’s correct operation and/or the safety of the installation.

It depends on the pump’s type and model.

Strictly follow the directions provided in the instruction manual.