The series offers different pumping solutions, from the pumping of liquids with solid parts in suspension to grinder pumps. Single-phase and three-phase motors are available, with built-in level regulator depending on the models.

Sturdy design

Corrosion

resistant

Practical and easy to use

Compliance with standards and directives

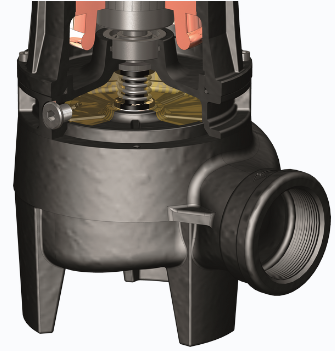

COMPATTA

Submersible electropumps with Vortex impeller

The Compatta Series is ideal to pump residential sewage thanks to its small size and mechanical characteristics.

Designed for draining wells, garages, cellars, basements, tanks, reservoir or places subject to flooding.

Use for irrigating gardens and vegetable plots and for supplying water to classic garden fountains

Maximum solids passage of 10mm.

Can be used in permanent or portable installations.

Available with a cable float (MA) or fixed float (MS).

| Model | Power KW / HP |

Voltage V |

Discharge in. |

Flow Rate L/min |

Head M |

|---|---|---|---|---|---|

| Compatta 1 M | 0.28/0.40 | 230 | 1 1/4" | 150 | 5,8 |

| Compatta 1.5 M/T | 0.37/0.50 | 230 ~ 400 | 1 1/4" | 180 | 7,5 |

| Compatta 2 M/T | 0.56/0.75 | 230 ~ 400 | 1 1/2" | 240 | 8,8 |

| Compatta 3 M/T | 0.75/1 | 230 ~ 400 | 1 1/2" | 270 | 10,8 |

| Model | Cycle (Hz) | A | B | N.W. (kg) |

| Compatta 1M | 50/60 | 375 | 191 | 12 |

| Compatta 1.5 M/T | 50/60 | 375 | 191 | 12.7 |

| Compatta 2 M/T | 50/60 | 375 | 191 | 13.8 |

| Compatta 3 M/T | 50/60 | 375 | 191 | 13.5 |

Technical data

Pressure: Hmax 13m, Qmax 33m³/h

Max temperature of the liquid: +40°C

Poles: 2

Permissible pH value: 6-10

Insulation class: F 155°C

Protection degree: IP68

Voltage: Single-phase 1~230V ±5% / Three-phase 3~400 ±5%

Max. immersion: 20 m

Materials

Main body: Cast Iron GG20

Motor side: Carbon/Ceramic (CA/CE/Viton)

Impeller: Vortex - Silicon carbide/Ceramic (SIC+CE/Viton)

Mechanical seals: double Mechanical Seal in oil chamber

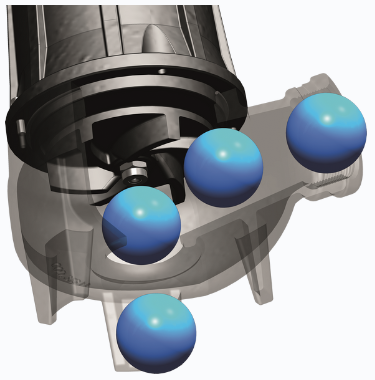

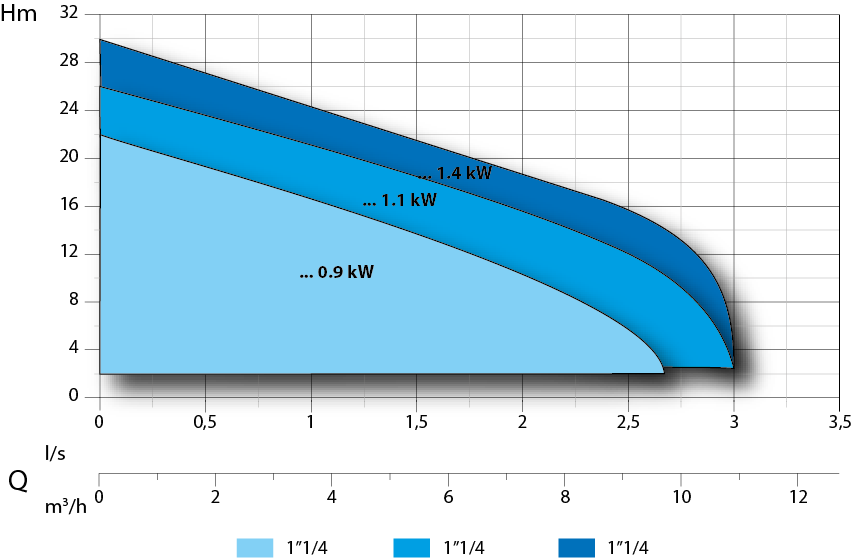

GRIX

Submersible electropumps with Cutting System

The Grix range of submersible pumps have an inbuilt macerator in the inlet. This breaks down solids in waste water which permits transport along relatively narrow, often pre-existing, pipes.

Designed for domestic sewage, liquids with suspended solids, whenever high pressure (Hm) is needed.

The pump has a radial macerator in the inlet. The blades are made of hardened steel guaranteeing maximal cutting efficiency.

Maximum solids passage of 6mm.

Can be used in permanent or portable installations.

| Model | Power KW / HP |

Voltage V |

Discharge in. |

Flow Rate L/min |

Head M |

|---|---|---|---|---|---|

| Grix 32-2/090 M/T | 0.9/1.2 | 230 ~ 400 | 1 1/4" | 165 | 21 |

| Grix 32-2/110 M/T | 1.1/1.5 | 230 ~ 400 | 1 1/4" | 180 | 25 |

| Grix 32-2/140 M/T | 1.4/1.9 | 230 ~ 400 | 1 1/2" | 180 | 28.5 |

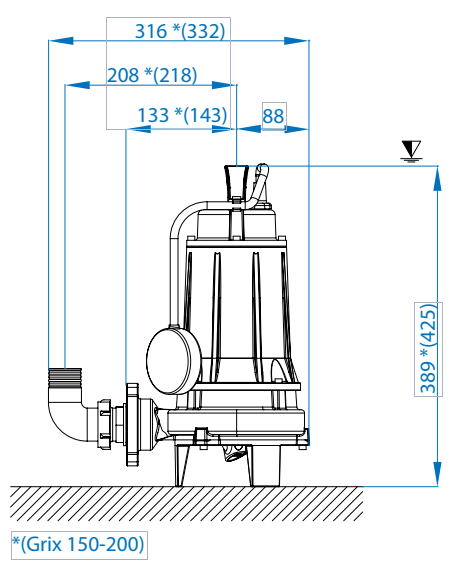

| Model | Cycle (Hz) | A | B | N.W. (kg) |

| Grix 32-2/090 M/T | 50/60 | 425 | 231 | 21 |

| Grix 32-2/110 M/T | 50/60 | 425 | 231 | 24.5 |

| Grix 32-2/140 M/T | 50/60 | 425 | 231 | 27 |

Technical data

Pressure: Hmax 28.5m, Qmax 11m³/h

Max temperature of the liquid: +40°C

Poles: 2

Permissible pH value: 6-10

Insulation class: F 155°C

Protection degree: IP68

Voltage: Single-phase 1~230V ±5% / Three-phase 3~400 ±5%

Max. immersion: 20 m

Materials

Main body: Cast Iron GG205

Motor side: Carbon/Ceramic (CA/CE/Viton)

Impeller: Cutter - Silicon carbide/Ceramic (SIC+CE/Viton)

Mechanical seals:

double

Mechanical Seal in oil chamber

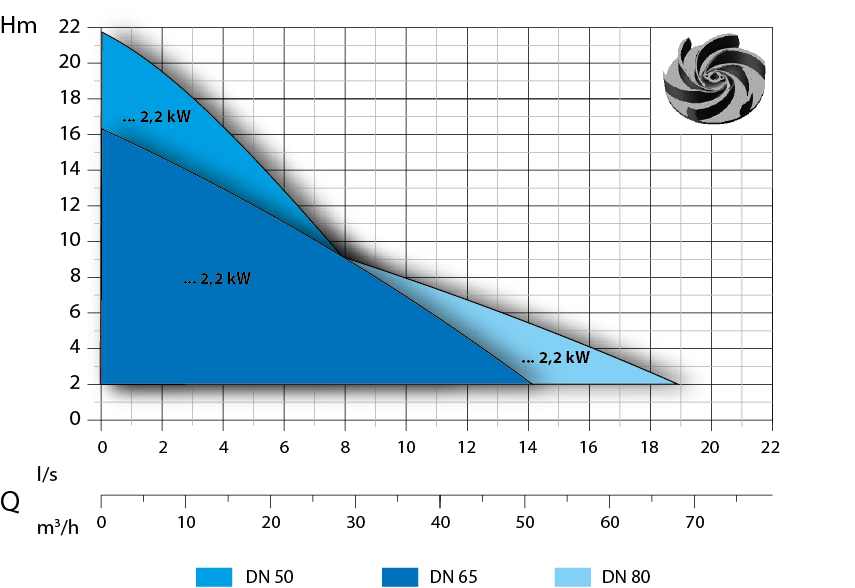

DNA

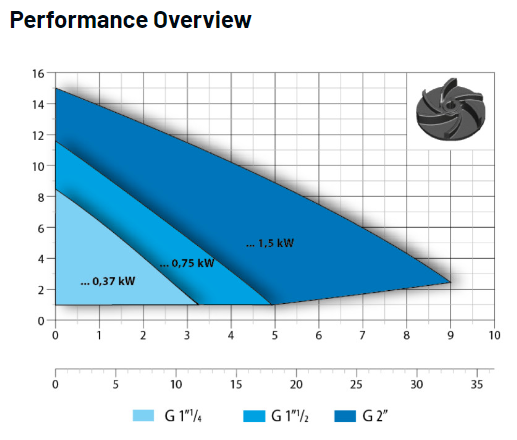

Submersible electropumps with Vortex impeller

The DNA Series is used for sewage and waste water. Its wide channel permits the free passage of solids rendering it particularly useful in water treatment plants, domestic, municipal and farming applications. The 4 pole version can be used applications where continuous S1 service is needed and are characterised by their quiet operation.

Designed for sewage and waste water.

Use for water treatment plants, domestic, municipal and farming applications

Free passage of 45mm, 50mm, 65mm, 75mm and 80mm.

Can be used in permanent or portable installations.

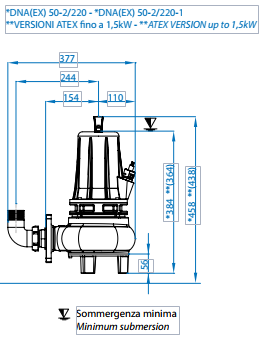

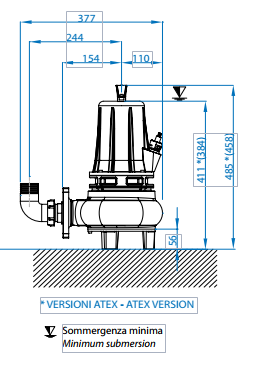

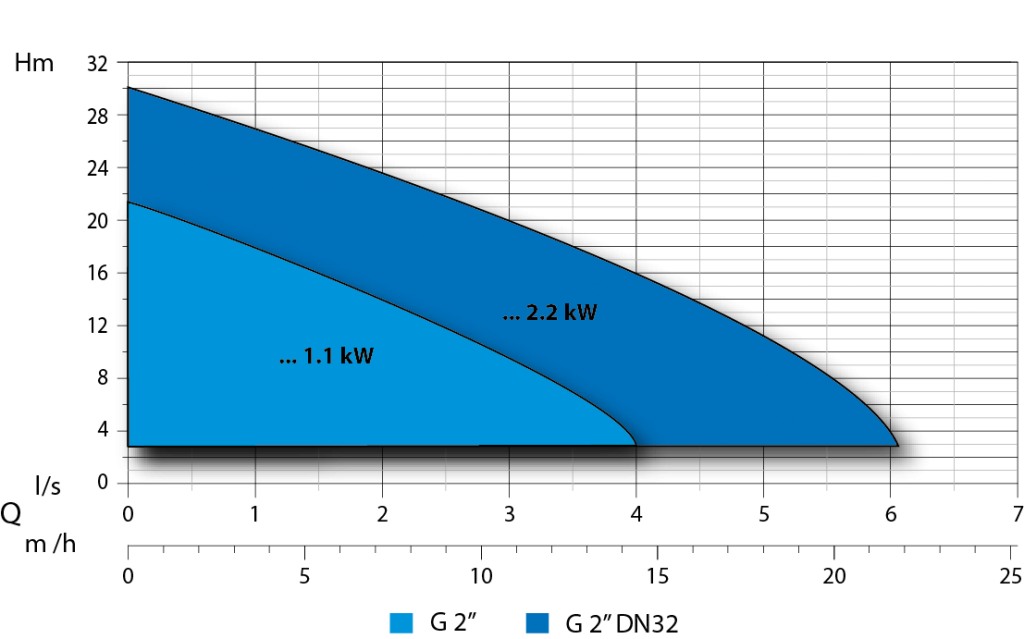

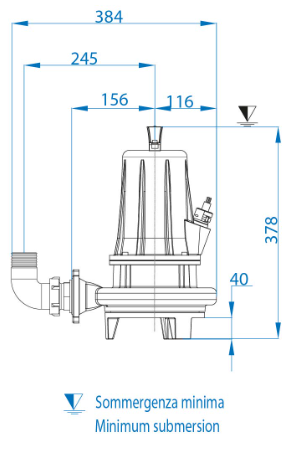

50-2

Horizontal Outlet DN50 PN10 - G 2” - RPM 2850 1/min 2 poles

| Model | Power KW / HP |

Voltage V |

Discharge in. |

Flow Rate L/min |

Head M |

|---|---|---|---|---|---|

| DNA 50-2/056 M/T | 0.56/0.75 | 230 ~ 400 | 2" | 420 | 7.5 |

| DNA 50-2/075 M/T | 0.75/1 | 230 ~ 400 | 2" | 480 | 9.5 |

| Model | Cycle (Hz) | A | B | N.W. (kg) |

| DNA 50-2/056 M/T | 50 | 428 | 220 | 18.5 |

| DNA 50-2/075 M/T | 50 | 428 | 220 | 19 |

| Model | Power KW / HP |

Voltage V |

Discharge in. |

Flow Rate L/min |

Head M |

|---|---|---|---|---|---|

| DNA 50-2/110 M/T | 1.1/1.5 | 230 ~ 400 | 2" | 480 | 7.5 |

| DNA 50-2/150 M/T | 1.5/2 | 230 ~ 400 | 2" | 550 | 9.5 |

| DNA 50-2/220 T | 2.2/3 | 230 ~ 400 | 2" | 600 | 18 |

| DNA 50-2/220-1 T | 2.2/3 | 230 ~ 400 | 2" | 600 | 20 |

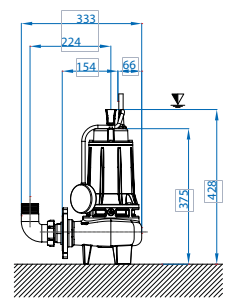

| Model | Cycle (Hz) | A | B | N.W. (kg) |

| DNA 50-2/110 M/T | 50 | 458 | 264 | 27.5 |

| DNA 50-2/150 M/T | 50 | 458 | 264 | 28.5 |

| DNA 50-2/220 T | 50 | 458 | 264 | 29.5 |

| DNA 50-2/220-1 T | 50 | 438 | 264 | 29.5 |

50-4

Horizontal Outlet DN50 PN10 - G 2” - RPM 1450 1/min 4 poles

| Model | Power KW / HP |

Voltage V |

Discharge in. |

Flow Rate L/min |

Head M |

|---|---|---|---|---|---|

| DNA 50-4/090 M/T | 0.9/1.2 | 230 ~ 400 | 2" | 450 | 5.2 |

| Model | Cycle (Hz) | A | B | N.W. (kg) |

| DNA 50-4/090 M/T | 50 | 485 | 264 | 29.5 |

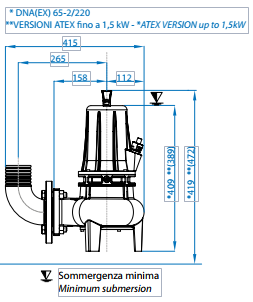

65-2

Horizontal Outlet DN65 PN10 - RPM 2850 1/min 2 poles

| Model | Power KW / HP |

Voltage V |

Discharge in. |

Flow Rate L/min |

Head M |

|---|---|---|---|---|---|

| DNA 65-2/110 M/T | 1.1/1.5 | 230 ~ 400 | 2 1/2" | 480 | 10 |

| DNA 65-2/150 M/T | 1.2/2 | 230 ~ 400 | 2 1/2" | 660 | 12 |

| DNA 65-2/220 T | 2.2/3 | 230 ~ 400 | 2 1/2" | 840 | 15 |

| Model | Cycle (Hz) | A | B | N.W. (kg) |

| DNA 65-2/110 M/T | 50 | 472 | 280 | 27.5 |

| DNA 65-2/150 M/T | 50 | 472 | 280 | 29.5 |

| DNA 65-2/220 T | 50 | 419 | 280 | 30 |

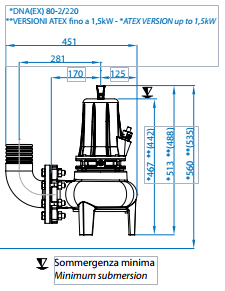

80-2/4

Horizontal Outlet DN80 PN16 - RPM 2850 1/min 2 poles - RPM 1450 1/min 4 pole

| Model | Power KW / HP |

Voltage V |

Discharge in. |

Flow Rate L/min |

Head M |

|---|---|---|---|---|---|

| DNA 80-2/110 M/T | 1.1/1.5 | 230 ~ 400 | 3" | 720 | 6.5 |

| DNA 80-2/150 M/T | 1.5/2 | 230 ~ 400 | 3" | 840 | 8.2 |

| DNA 80-2/220 T | 2.2/3 | 230 ~ 400 | 3" | 960 | 12.5 |

| DNA 80-4/090 M/T | 0.9/1.2 | 230 ~ 400 | 3" | 720 | 4.8 |

| Model | Cycle (Hz) | A | B | N.W. (kg) |

| DNA 80-2/110 M/T | 50 | 535 | 295 | 31.5 |

| DNA 80-2/150 M/T | 50 | 535 | 295 | 34 |

| DNA 80-2/220 T | 50 | 560 | 295 | 34.5 |

| DNA 80-4/090 M/T | 50 | 535 | 295 | 37.5 |

Technical data

Pressure: Hmax 21m, Qmax 57,6 m³/hMax.

temperature of the liquid: +40°C

Poles: 2 - 4

Permissible pH value: 6-10

Insulation class: F 155°C

Protection degree: IP68

Voltage: Single-phase 1~230V ±5% / Three-phase 3~400 ±5%

Max. immersion: 20 m

Materials

Main body: Cast Iron GG20

Motor side: Carbon/Ceramic (CA/CE/Viton)

Impeller: Vortex -

Silicon carbide (SIC/SIC/Viton)

Mechanical seals: double

Mechanical Seal in oil chamber

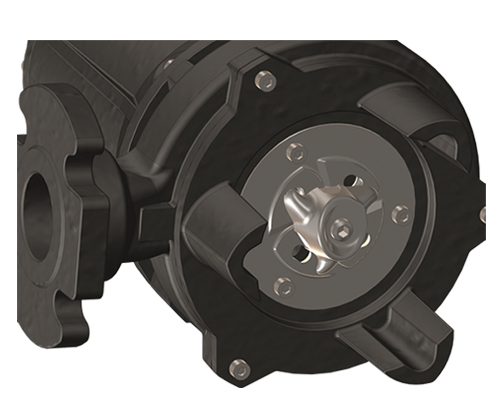

GX

Submersible electropumps with Cutting system

Series with suction grinding system, the reduced size of the pump combined with an efficient grinding system, makes the series flexible and effective.Ideal for sewage with filamentous and fibrous bodies. Available with ATEX certification (for use with liquids in explosive atmospheres)Flanged outlets

| Model | Power KW / HP |

Voltage V |

Discharge in. |

Flow Rate L/min |

Head M |

|---|---|---|---|---|---|

| GX 50-2/090 M/T | 0.9/1.2 | 230 ~ 400 | 2" | 210 | 16 |

| GX 50-2/110 M/T | 1.1/1.5 | 230 ~ 400 | 2" | 240 | 18.5 |

| GX 50-2/150 M/T | 1.5/2 | 230 ~ 400 | 2" | 300 | 21 |

| GX 50-2/220 T | 2.2/3 | 400 | 2" | 360 | 26.5 |

| Model | Cycle (Hz) | A | B | N.W. (kg) |

| GX 50-2/090 M/T | 50 | 378 | 272 | 24.5 |

| GX 50-2/110 M/T | 50 | 378 | 272 | 24.5 |

| GX 50-2/150 M/T | 50 | 378 | 272 | 33.5 |

| GX 50-2/220 T | 50 | 398 | 272 | 33.5 |

Technical data

Pressure: Hmax 25m, Qmax 22 m³/h.

Max temperature of the liquid: +40°C

Poles: 2

Permissible pH value: 6-10

Insulation class: F 155°C

Protection degree: IP68

Voltage: Single-phase 1~230V ±5% / Three-phase 3~400 ±5%

Max. immersion: 20 m

Materials

Main body: Cast Iron GG20

Motor side: Carbon/Ceramic (CA/CE/Viton)

Impeller: Grinder - Silicon carbide/Ceramic (SIC+CE/Viton)

Mechanical seals: double

Mechanical Seal in oil chamber