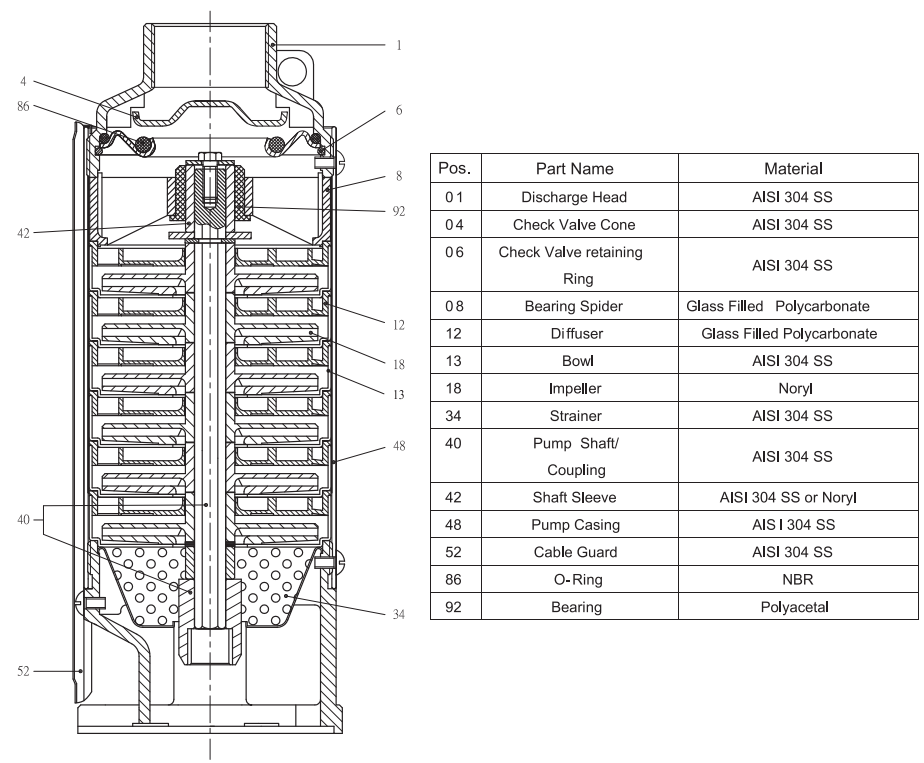

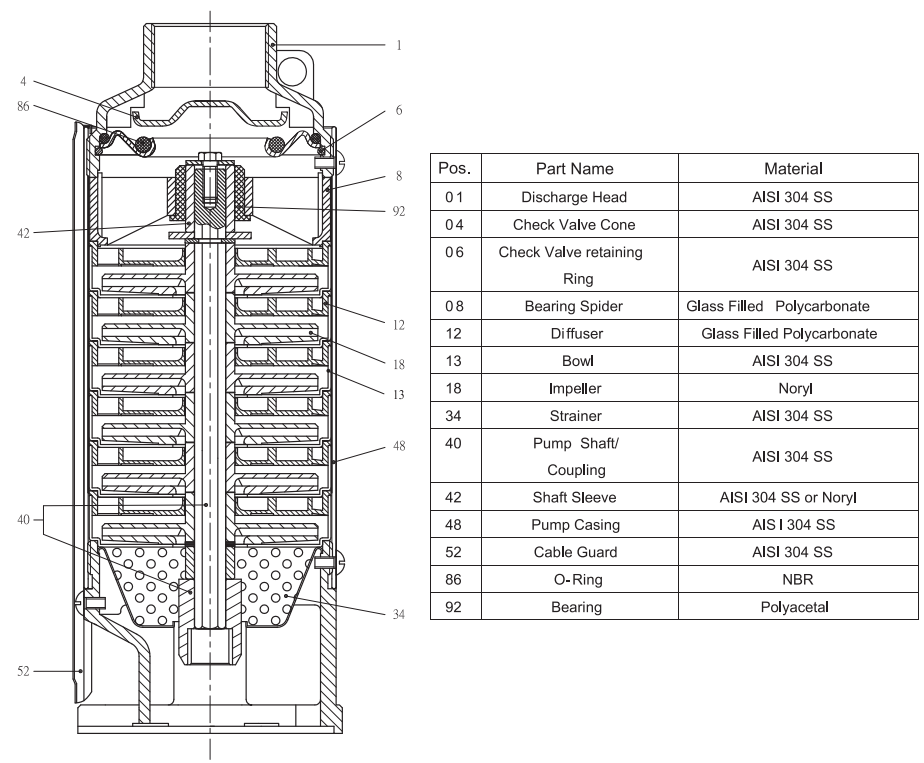

Stairs 4" ST series of pumps are manufactured using high quality materials and are designed to deliver years of dependable service. Pumps are on the floating impeller design which reduces starting torque requirements and reduces the effects of sand in the water.

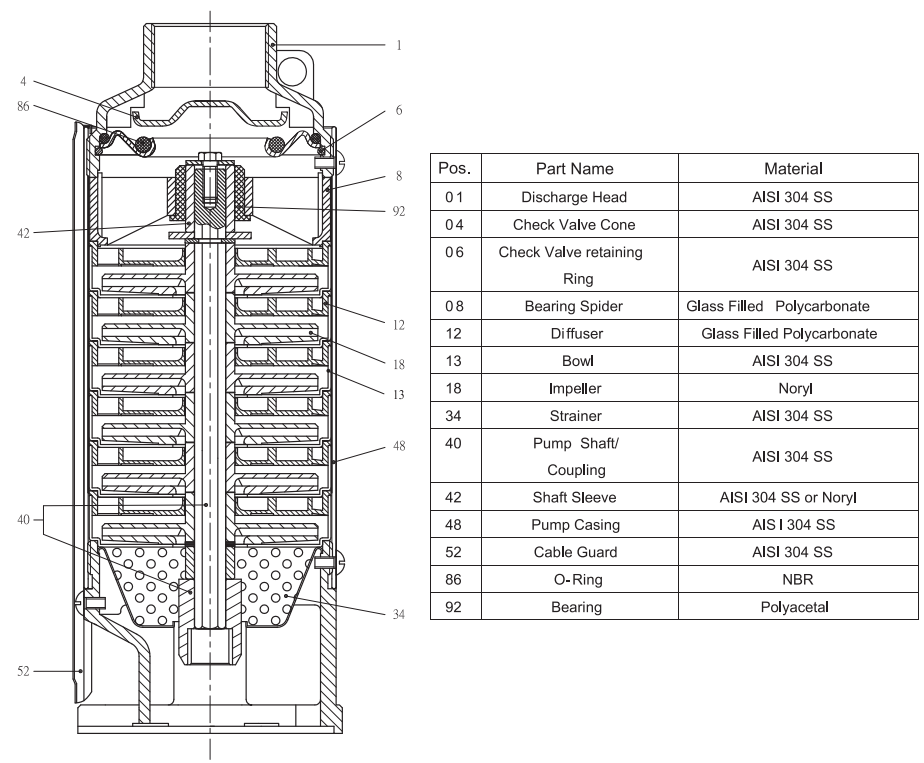

Discharge Head and Motor Adaptor are precision machined cast 304 stainless steel for superior strength and durability. The motor adaptor is NEMA standard.

Bearing is made with Polyacetal for strong wear and abrasive resistance.

Shaft Coupling is made from 304 stainless steel for easy alignment to the motor shaft.

Non-Return valve made from 304 stainless steel, fitted in the discharge to prevent any back flow of water and alleviate any water hammer to the pump.

Impellers are floating type made with Noryl* for a superior sand handling. Together with glass filled polycarbonate diffusers make the super strong pumps formaximum wear and abrasive resistance.

The materials are FDA complaint materials.

Impeller Bowls are made from 304 stainless steel, maximizing wear from abrasion.

Strainer is made from stamped 304 stainless steel for rigidity.

Pump Shaft is made from hex 304 stainless steel bar material for high corrosion resistance.

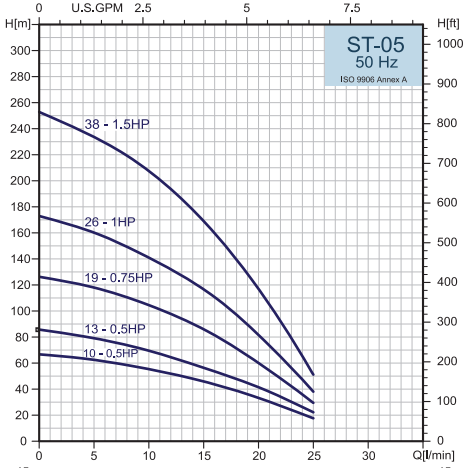

| Model | Power KW / HP |

Voltage V |

Inlet in. |

Flow Rate L/min |

Head M |

|---|---|---|---|---|---|

| 05-10 | 0.37/0.5 | 230 | 1 1/4" | 25 | 67 |

| 05-13 | 0.37/0.5 | 230 | 1 1/4" | 25 | 86 |

| 05-19 | 0.55/0.75 | 230 | 1 1/4" | 25 | 126 |

| 05-26 | 0.75/1 | 230 | 1 1/4" | 25 | 173 |

| 05-38 | 1.1/1.5 | 230 | 1 1/4" | 25 | 253 |

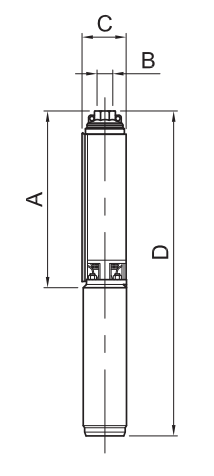

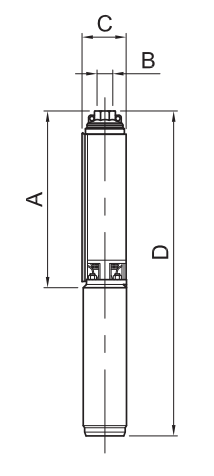

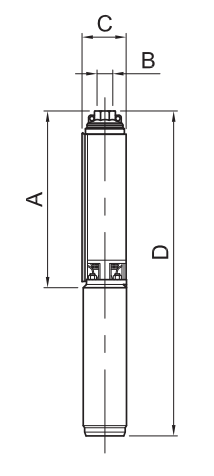

| Model | Cycle (Hz) | A | B | C | D | N.W. (kg) |

| 05-10 | 50 | 324 | 1 1/4" | 98 | 670 | 10.6 |

| 05-13 | 50 | 377 | 1 1/4" | 98 | 723 | 11.0 |

| 05-19 | 50 | 481 | 1 1/4" | 98 | 846 | 12.9 |

| 05-26 | 50 | 642 | 1 1/4" | 98 | 1022 | 14.6 |

| 05-38 | 50 | 864 | 1 1/4" | 98 | 1307 | 19.2 |

| Model | Power KW / HP |

Voltage V |

Inlet in. |

Flow Rate L/min |

Head M |

|---|---|---|---|---|---|

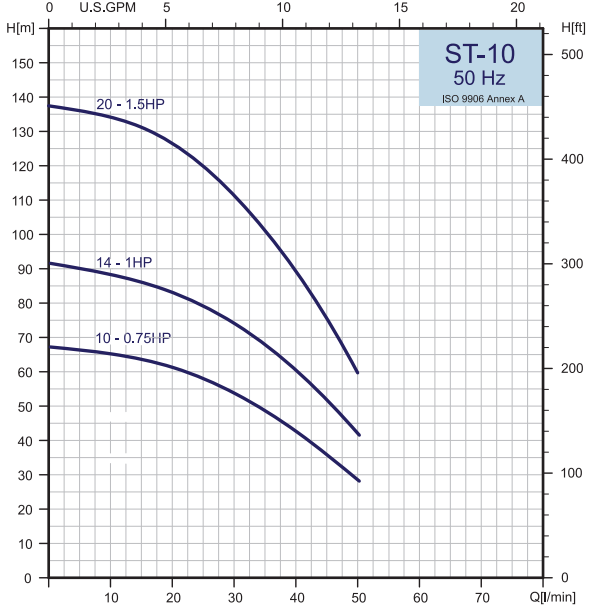

| 10-10 | 0.55/0.75 | 230 | 1 1/4" | 25 | 67 |

| 10-14 | 0.75/1 | 230 | 1 1/4" | 25 | 92 |

| 10-20 | 1.1/1.5 | 230 | 1 1/4" | 25 | 139 |

| Model | Cycle (Hz) | A | B | C | D | N.W. (kg) |

| 10-10 | 50 | 324 | 1 1/4" | 98 | 689 | 11.5 |

| 10-14 | 50 | 394 | 1 1/4" | 98 | 774 | 12.7 |

| 10-20 | 50 | 499 | 1 1/4" | 98 | 904 | 14.9 |

| Model | Power KW / HP |

Voltage V |

Inlet in. |

Flow Rate L/min |

Head M |

|---|---|---|---|---|---|

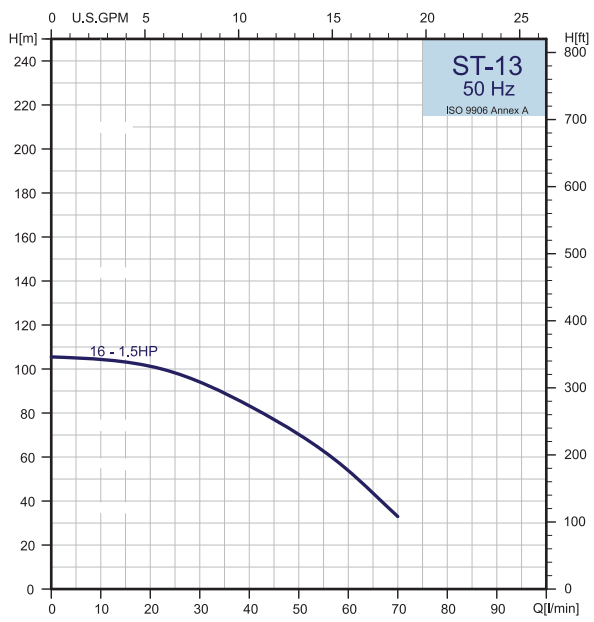

| 13-16 | 1.1/1.5 | 230 | 1 1/4" | 70 | 106 |

| Model | Cycle (Hz) | A | B | C | D | N.W. (kg) |

| 13-16 | 50 | 430 | 1 1/4" | 98 | 835 | 14.2 |

- Control box or thermals in the sun or near heat source.

- Incorrect thermals or control box fitted.

- Low line voltage.

- Phase failure (3 phase only).

- Faulty motor

- Water level in bore too low.

- Check valve installed backwards or stuck closed.

- Inlet screen on pump clogged.

- Hole in delivery piping below bore top.

- Motor failure.

- Broken pump shaft or coupling.

- Pump rotating backwards (3 phase only).

- Water level too low in bore.

- Discharge piping clogged, corroded or ruptured.

- Pump installed too low in bore and covered in sand or other solids.

- Inlet screen partially clogged.

- Worn pump.

- Check valve stuck partially closed.

- Motor related problem.

- Water logged pressure tank.

- Pressure switch differential adjustment incorrect.

- Pressure tank too small.

- Other control problems (eg. probes too close).

- Fuses too small.

- Fuse receptacles dirty or corroded.

- Loose connection in fuse box.

- Defective incoming power leads.

- Ground wire connected to wrong terminal.

- Motor failure.

- Incorrectly wired incomingpower leads.

- Ground wire connected to motor control equipment.

- Defective motor starter or control box.

- Incorrectly grounded motor.

- Water level too low in bore.

- Pump earthing to ground through poor splice connection or chaffing.

- Unsatisfactory pH levels.

- Active single wire earth return electrical distribution system.